Our technology and its development:

A Liquid Desiccant Cooling System (L-DCS) is used to dehumidify air and / or cool air of a building. The core idea of this technology is the attempt to separate the air conditioning in their individual process steps (dehumidification and cooling), and to process them independently. In this way, the possibility of one or both sub-steps allow using innovative technologies that use instead of electricity other sources of power as such as heat. This offers the possibility of utilizing waste heat, which usually gets released unused into the atmosphere, e.g. by example:

• Cogeneration (CHP)

• District heating

• Solar thermal systems (flat collectors)

• Geothermal energy

• Waste heat of compressed air compressors

• Heat from various industrial processes (steel production, food industry, chemical industry, etc.)

The actual technology goes back to the first developments in the early 19th century and is based on the direct absorption of water vapor on a hygroscopic liquid, mostly concentrated aqueous solution of lithium chloride (LiCl-H2O). This sorbent absorbs water from the air and dilutes itself. The absorbed water can be driven with low temperature heat. A flow temperature of about 55-75 ° C is sufficient to power the dehumidification process. The sorbent is not consumed and can be reused indefinitely.

The reason why these benefits were not harvested so far, was the high corrosive forces of the sorbent, which made the use of conventional materials (steel ..) impossible. Only in recent years it has become possible by new plastic materials and new production processes to design and build machines that meet both, the technical as well as the economic challenges of the modern world.

For air condition operators not only the efficient dehumidification of the air, but increasingly also ecological requirements are of interest such as:

• High energy efficiency

• Integration into renewable-powered systems

• Integration in industrial energy efficiency policies

• Efficient use of resources to manufacture the air condition system

• Recyclability

The innovative part of the technology is the actual air drying. Subsequent cooling of the air is optional and can be prepared by conventional systems using adiabatic- or indirect evaporative cooling .

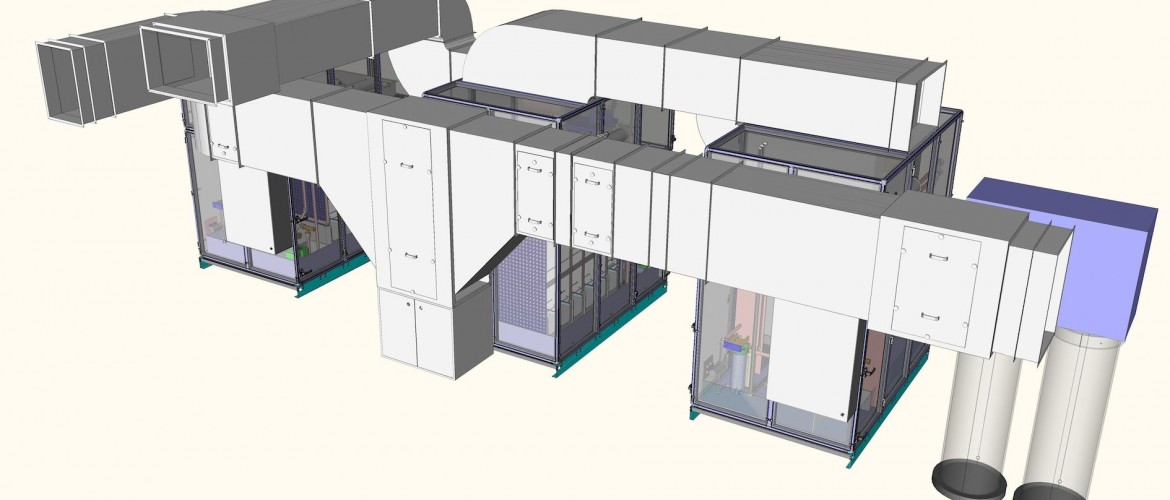

Completely integrated system, individual components and their function

Cooling of the supply air by means of evaporative cooling is omitted in the following description of the system. Such configuration is particularly suited for use in wet, tropical climates.

The complete liquid desiccant cooling (L-DCS) configuration consists of

- aregenerator,

- an energy storageand

- the actualventilationsystem, which is designed fordehumidification of fresh airwith

- energy recoveryfrom exhaust air.

The ventilation system consists of an absorber and a heat exchanger in the inlet air and an indirect evaporative cooler in the exhaust air flow.

Prior to entry into the building, fresh air from the environment is dehumidified in the absorber at near ambient temperature and then subsequently cooled in the heat exchanger.

The heat freed during the dehumidification and cooling processes get transferred to the cooling water circuit and transported into the evaporative cooler sitting in the building exhaust air stream. The cooling effect in the evaporation cooler is achieved by the evaporation of water in the exhaust air stream. The evaporative cooling is hereby transferred in countercurrent flow to the cooling water flow. In this way, the cooling potential of the building exhaust air is recovered in an thermodynamically optimal way.

The water extracted from the fresh air is absorbed in the absorber by the sorbent. Therefore the absorber receives concentrated sorbent from the storage tank, which dilutes by the uptake of water. Subsequently, it is returned in this diluted state into the storage tank I. The fresh air flow can be continuously dehumidified as long as tank I provides the dehumidification energy in the form of concentrated sorbent.

The capacity of this energy storage device is adapted to the requirements of any amount by adjusting the tank sizes. The dehumidification energy is released only upon direct contact of the sorbent with ambient air. The storage of dehumidification energy is loss less as long as the tank is sealed from ambient air. Dehumification energy may therefore stored lossless any length of time, whether it be stored just over an hour, a day, a week or even seasonal. In order that the sorbent can be continuously used again the water taken in during absorption must be expelled again. This desorption process takes place in the regenerator.

The heat recovery in the regenerator exhaust reduces heat losses and increases the efficiency of the system.

Diluted sorbent is supplied to the regenerator continuously from the storage tank I and distributed on the exchange surfaces of the regenerator forming there a uniform thin film. This film is in contact with air and gets heated by hot water circulating within the exchange surfaces to about 55 ° -75 ° C. This heating expels the excess water from the sorbent into the air stream and from there it is released into the environment. Concentrated sorbent exiting the regenerator is supplied to the storage tank II and there is again ready for air dehumidification.

L-DCS technology managed to develop of an ultra-low-flow technology reducing the amount of sorbent used for dehumidification so much that the absorption of water causes a substantial dilution of the sorbent. The dilution is a measure of the absorbed water during the dehumidification of the air volume and thus a measure of the energy which had to be used. The higher the dilution, the more energy can be converted from a given quantity of sorbent.

Depending on the initial humidity a dilution of the sorbent of over 10% is feasible. This corresponds to an energy density of about 250kWh per m³ dehumidification capacity of the sorbent.

Another major advantage of the ultra-low-flow technology is the fact that you can achieve great dehumidification with a very small flow of the sorbent volume. So even large dehumidification energy capacity can be transported through very small uninsolated tubes. Since the sorbent loses its dehumidification capacity only when in contact with air, the storage and the transport of energy is lossless if the pipelines and tanks are airtight

Since the dehumidification is not reached on an thermal way, one does not need to insulate these pipes and tanks which reduces installation costs.